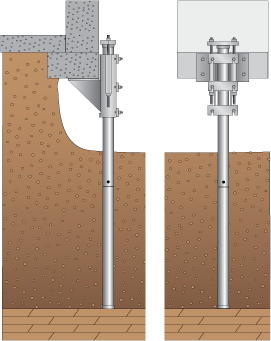

Steel Pier Lifting

ECP Steel Piers Advantages™

ECP Steel Piers Advantages™

- ECP Steel Piers and specialized tools have been designed and engineered to perform. The products are manufactured in a state of the art, high tech facility using mill certified materials and welded by certified welders.

- ECP Steel Piers have been tested and proven in all soil types to provide stability and performance.

- Each ECP Steel Pier is individually load tested on site to insure a higher load capacity than required to support the structure. This Factor of Safety insures that the settlement problems are over and the likelihood of returns for "adjustments" is highly unlikely.

- All installing contractors have been trained and approved to install ECP Steel Piers.

- Skilled technicians perform the installation, testing and restoration operations.

- No large equipment is necessary to install the ECP Steel Pier so there is minimal impact on the lawn and shrubs.

- ECP Steel Piers are specifically designed to eliminate as much skin friction as possible, thus "down drag" from consolidating soil is not a problem and does not affect the pier.

- ECP Steel Piers have been installed to depths exceeding 120 feet to a verified suitable bearing stratum.

- Installers document the project by recording the installation force on the pier, the depths to verified bearing and the final pier working loads after restoration.

- ECP training dictates that an even and gentle restoration process be used to lift the structure. Large groups of piers, or all of the piers, are gently loaded simultaneously; thus insuring the minimum amount of stress is applied to the structure during restoration.

- No soil need be stacked and hauled from the site. The small excavations required to install the ECP Steel Pier are filled with the removed soil.

- No waiting a week for concrete to cure. Once all ECP Steel Piers have been installed, restoration begins immediately. Most projects are finished in a few days.